General Fabrication Services

Achieve the right balance of strength, performance, and efficiency with Frigate’s general fabrication services. Engineered for industrial, commercial, and infrastructure projects, our solutions ensure durable metal components with high structural integrity and long service life.

Our Clients

Preferred by Those Who Demand the Best

High-Strength Metal Fabrication for Diverse Industries

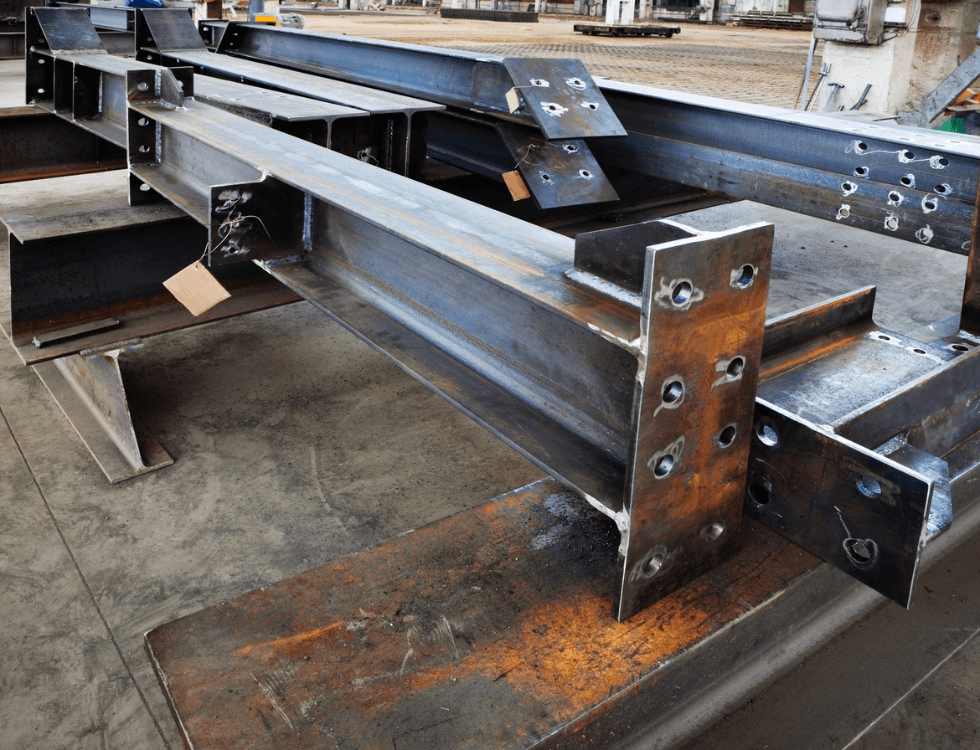

Every fabricated component undergoes precise cutting, welding, and forming to match application-specific needs. Frigate processes materials such as stainless steel, carbon steel, and aluminum to maintain strength, load-bearing capacity, and durability.

Heat treatment and mechanical finishing enhance surface hardness and corrosion resistance. Additional processes like edge rounding, hole punching, and structural reinforcement improve the functionality of fabricated parts, ensuring long-lasting performance.

Accurate Cutting, Welded Joints, and Surface Coatings for Reliable Fabrication

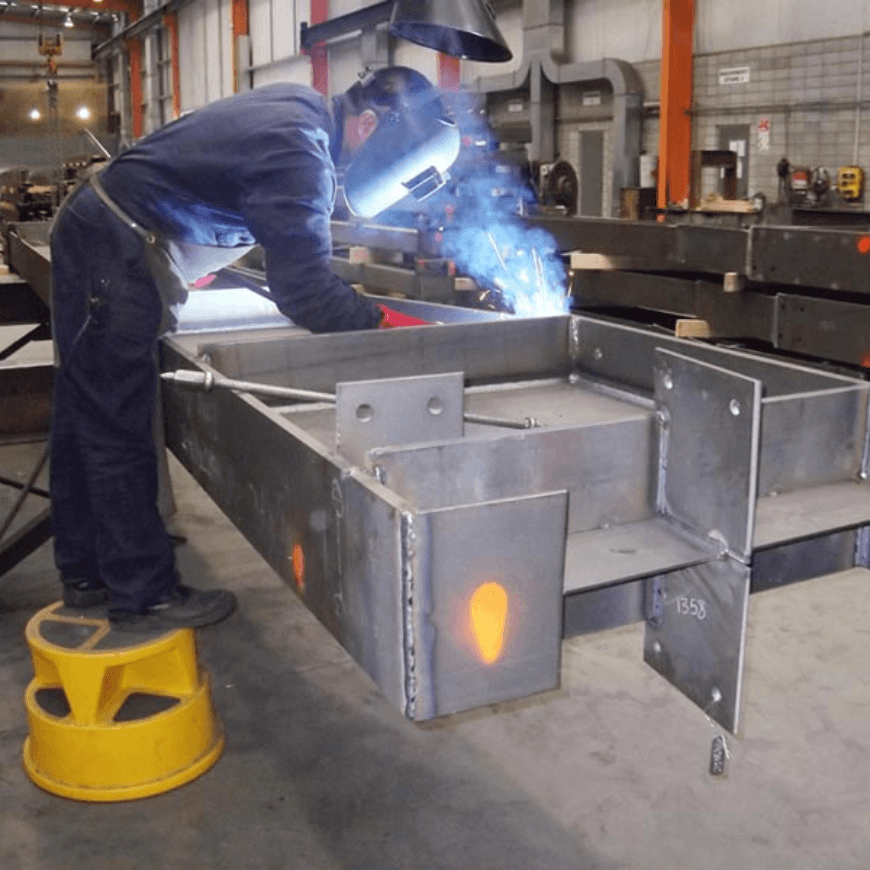

Structural strength and assembly quality rely on accurate cuts, proper welding, and protective coatings. Plasma, oxy-fuel, and water jet cutting ensure clean edges with minimal distortion. Each cut component undergoes inspection for thickness, edge smoothness and dimensional accuracy. We select our welding techniques, such as spot, arc, resistance or pull through welding, based on material thickness and load-bearing needs.

Post-weld stress relief treatments and penetration testing confirm structural integrity, preventing fatigue failure. Press forming, roll bending, and stamping create uniform shapes, reinforcing enclosures and brackets with stiffeners and gussets. Our protective coatings, including galvanizing, powder coating, and epoxy painting, shield structures from corrosion. Surface preparation through shot blasting and polishing enhances adhesion, with testing ensuring long-lasting protection.

The Processes We Handle

Carrying out Critical Fabrication Tasks with Focus on Quality

Our Streamlined Workflow

Ensuring low-maintenance structures with fast installation and superior load-bearing capacity

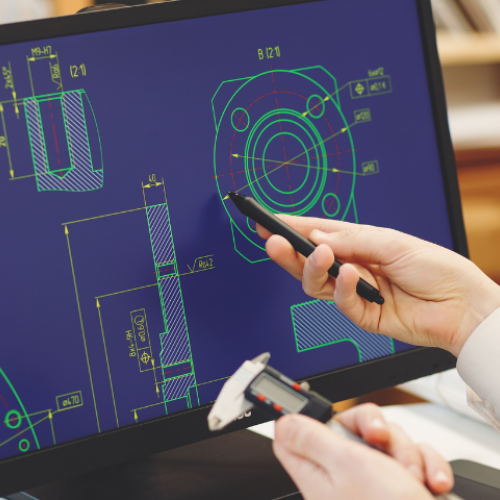

Structural Analysis & Load Assessment

Fabrication & Component Preparation

Quality Checks & Surface Protection

Logistics Coordination & Installation

- Faster project completion

- Large-scale production

- Uninterrupted supply

- Lower overall expenses

- Higher profit margins

- Reduced transit delays

Our Track Record of Excellence

Transforming Challenges into Success Stories

Expertly Executed Projects Across Key Industrial Sectors

Streamlined storage solutions with rack-supported structures and integrated dock levelers. Steel bracing systems ensure efficient load transfer for multi-level storage operations.

Seamless integration of overhead cranes, conveyor systems, and automated assembly lines. Custom bay spacing and truss designs support heavy machinery and optimize operational efficiency.

Long-span trusses create spacious, unobstructed storage for aircraft and military equipment. Compliance with fire safety and blast resistance standards ensures robust facility protection.

Aesthetic steel facades, insulated roofing, and modular offices offer flexible design options. Pre-engineered construction reduces timelines for large-scale commercial projects.

Aesthetic steel facades, insulated roofing, and modular offices offer flexible design options. Pre-engineered construction reduces timelines for large-scale commercial projects.

Aesthetic steel facades, insulated roofing, and modular offices offer flexible design options. Pre-engineered construction reduces timelines for large-scale commercial projects.

Get a Custom Quote for your Fabrication work!

Submit your inquiry to explore fabrication options suited to your requirements.

Applications We Serve

Frames, enclosures, and protective housings are built for impact resistance. Reinforced welding and machining ensure seamless integration with industrial systems.

Beams, columns, and platforms meet engineering load standards. Corrosion-resistant finishes improve durability for outdoor and high-load applications.

Power distribution enclosures, busbars, and substation structures are designed for conductivity and mechanical strength. Coated surfaces ensure resistance to environmental factors.

Fabricated chassis, mounting brackets, and body panels maintain structural integrity under high stress. Surface treatments protect against wear, heat, and corrosion.

Long-Lasting Strength with Proven Fabrication Techniques

Every fabrication project is subjected to rigorous quality control processes, ensuring superior strength and durability. Stress testing, dimensional verification, and material analysis guarantee that all components meet stringent industry standards. With expertly welded joints, the fabricated parts deliver long-lasting performance in demanding environments.

By optimizing production efficiency and minimizing material waste, projects are delivered faster without sacrificing quality. Precise assembly and streamlined processes provide cost-effective solutions, ensuring your industrial applications run smoothly and reliably for the long haul.

Our Ongoing and Completed Projects

Presenting superior work through real-time project visuals

Hear from Our Satisfied Clients

Delivering consistent quality and reliable execution for every project

Your Questions Answered

Find Clear, expert-backed explanations for your fabrication concerns.

What fabrication methods does Frigate use for high-strength metal components?

How does Frigate ensure durability in fabricated metal structures?

Can Frigate handle large-scale structural fabrication projects?

What payment terms does Frigate offer for fabrication projects?

How does Frigate reduce material waste and rework in fabrication?

Let’s Build Something Great

Fill out the form below and our team of experts will get back to you shortly!

Get in Touch with us Today

Our team is ready to provide the support and expertise you need.